1. Use a specially designed knife-shaped gear to press small holes on the tin wire, so that the flux will vaporize when the soldering iron is heated, and overflow from the hole, effectively preventing the occurrence of "tin burst" and greatly reducing The appearance of solder balls avoids the generation and splashing of solder balls.

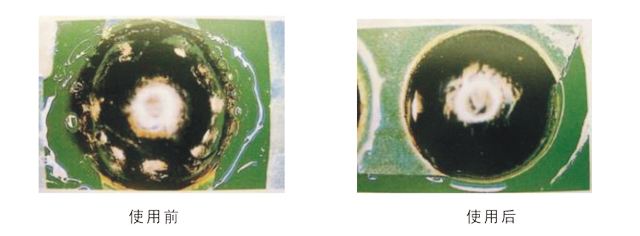

2. Quickly activate the flux to create an ideal soldering environment, enhance the solderability and fluidity of the solder, and make the soldering surface very beautiful.

3. Avoid the cleaning process after welding and effectively reduce defective products.

4. The body is compact, saving space.

model | 372B |

power | 6W |

Applicable tin wire diameter | 0.8- 1.2mm (can be customized according to customers) |

Dimensions | 76 (W) × 107 (H) × 168 (L)mm |

weight | 1.7 kg (including foot switch) |